BRAKING SYSTEMS

It is important to know and understand how the braking systems work on a commercial vehicle. In addition there are other systems that in conjunction with your brakes control the speed of your vehicle.

There are three main braking systems fitted to LGV’s, the service brake known as the principal braking system, secondary and parking brake (handbrake).

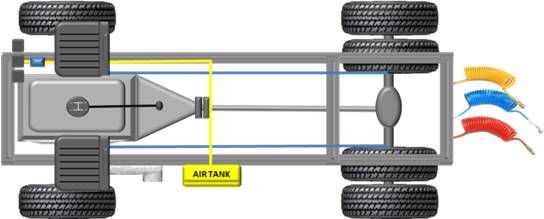

The air braking system is easy to understand, air is drawn in through the air intake. It then passes through an air compressor, and is then stored under pressure in a number of air tanks. When the hydraulic foot brake is depressed, air is released through a distribution valve to the brakes on the vehicle. If you have a trailer, it simultaneously activates the brakes via the yellow service line.

Modern vehicles have only two air lines that need connecting, they are the Red (Emergency) and the Yellow (Service line). Caution should be taken when connecting these air lines as they are both under pressure. Make sure that you have a firm grip of the couplings when connecting.

On older vehicles there is an additional line called the auxiliary line, this is a blue airline. On most trailers there is no coupling for the blue line, all you need to do is stow the blue line away safely.

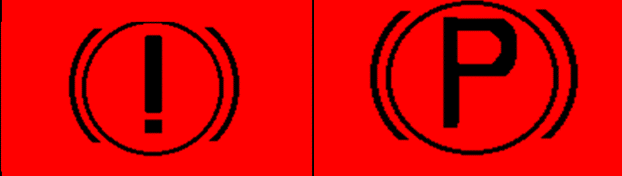

All air brake systems need to have sufficient air stored in the air tanks in order for the brakes to be effective. In the cab you will have air warning lights and in some cases a warning buzzer.

The lights and the buzzer will go out once the air system has reached a safe working pressure. This is achieved by running the engine as the air compressor is driven

The lights and the buzzer will go out once the air system has reached a safe working pressure. This is achieved by running the engine as the air compressor is driven

by the engine. Do not attempt to release the parking brake and drive if the

warning lights and buzzer are on.

If the pressure is not sufficient the service brake might not stop you. If for any reason the warning lights do come on after you start moving, you must stop immediately in a safe place and seek assistance.

Because air brakes can be quite sharp, modern day vehicles have been fitted with a hydraulic foot-brake (air assisted hydraulic brakes). You can experience faults with this.

The brake pedal can become very hard, you will not be able to depress the foot-brake, this is because the vacuum pump inside the pedal is not working. You could also find that when you depress the foot-brake pedal there is no resistance and the pedal travels down to the floor with minimum effort. The most likely cause of this is a lack of hydraulic fluid.

The air used to supply your brake systems is drawn from outside the vehicle, it passes through an air cleaner then it is compressed and stored for use.

Moister from the atmosphere and road surface water can also be drawn into the braking system.

In winter the water can freeze in the pipes, causing a reduction in your brakes effectiveness. You can avoid this problem by draining your air tanks manually. On more modern vehicles this will be done automatically, you will need to consult the vehicle handbook for the correct procedure.

If you continually use your brakes, especially on downhill slopes, because of the excessive weight that these vehicles carry you will experience brake fade.

Brake fade is a reduction in the brakes effectiveness. The brake linings overheat and burn. This changes the configuration of the linings and you will not be able to stop.

Brake fade is a reduction in the brakes effectiveness. The brake linings overheat and burn. This changes the configuration of the linings and you will not be able to stop.

When approaching a downhill slope you will get warnings of the impending slope and the degree of the hill. Before descending the hill change down to a low gear, this will help you maintain control of the vehicle, it is known as engine braking.

To minimise brake fade additional systems have been fitted within the transmission system that will in conjunction with your brakes, slow your vehicle down safely avoiding brake fade.

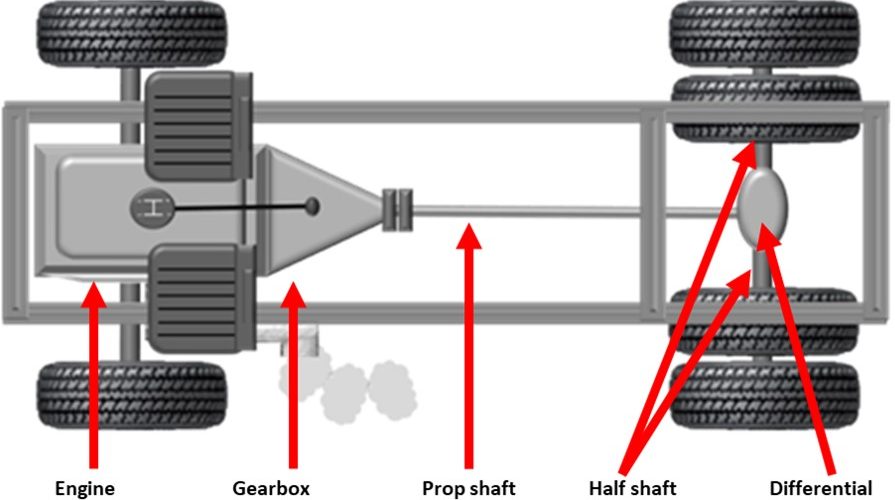

All components that make the road wheels turn are called the transmission system:

ENGINE BRAKING:

Before descending downhill it is advisable to select a lower gear, this will slow the vehicle down giving you greater control. changing to a lower gear is classed as engine braking.

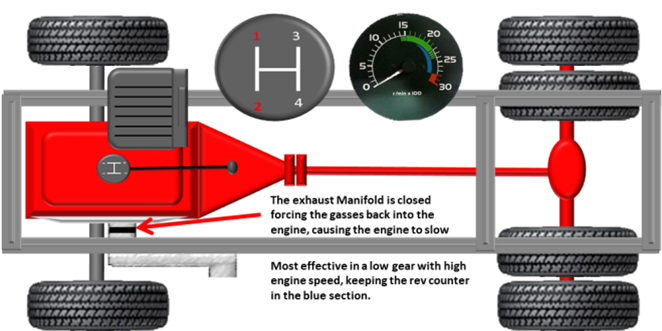

EXHAUST BRAKE:

The internal combustion engine has four strokes, Suck, Squeeze, Bang, Blow. If you take or slow down one of these strokes, you will restrict the engine from functioning properly. The exhaust brake is a system that does just that. The brake can work automatically via a switch in the cab, or manually via a foot control.

When operated it restricts the exhaust gases from escaping via a valve in the manifold, forcing them back into the engine, creating back pressure.

The effect of this will slow the transmission system down and in turn the road wheels. The exhaust brake works best in a low gear and high engine speed keeping the revs in the blue band on the rev counter. The exhaust brake only works on the prime mover and not a trailer, so you must be careful when operating.

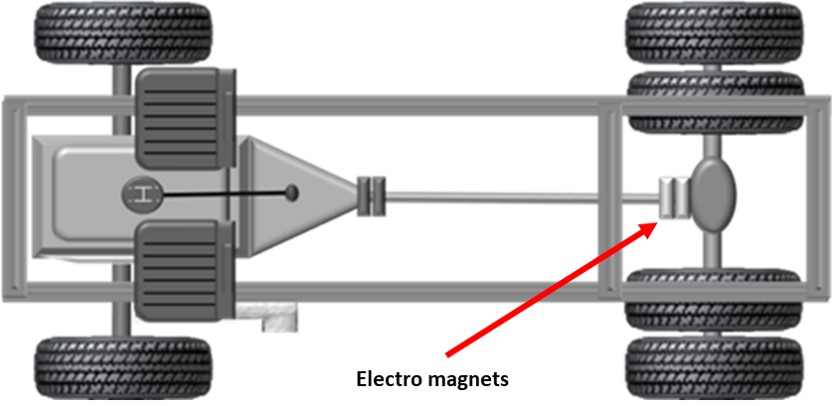

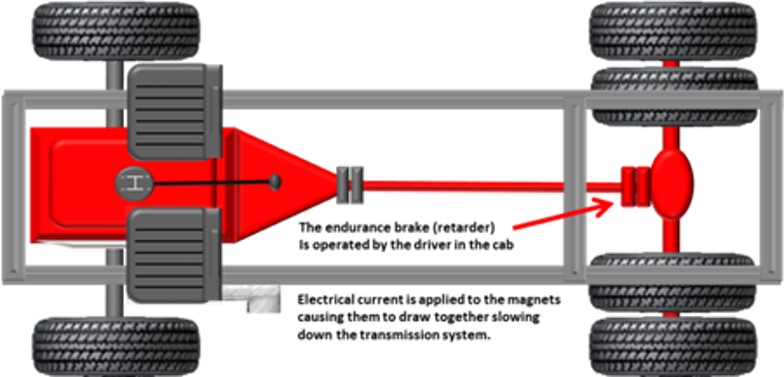

ENDURANCE RETARDER:

A system for controlling the vehicle’s speed without using the foot-brake is called an endurance brake or retarder. It replaces some of the functions of friction-based brakes which are susceptible to brake fade on long downhill slopes.

The retarder isn’t usually capable of bringing a vehicle to a standstill, so you have the normal friction-based service brakes for that. These systems mean your brake linings last longer.

Electromagnetic retarders work by applying a magnetic resistance to the prop shaft which, in turn, slows down the wheels. This allows the service brake to stay cool for optimum performance when required. When driving on snow or ice resistance will be lost. This will result in your wheels locking up and you loosing control.

JAKE BRAKE:

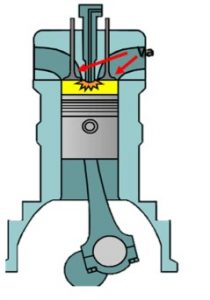

A Jake Brake modifies the timing on the exhaust valves so that, when braking is desired, the exhaust valves opens as the piston reaches the top of the compression stroke.

The energy gathered in the compressed air is released, so the compression stroke actually provides braking power.

For the purpose of the test, it adjusts the valve timings. 🙂

It is important to remember that you use the additional systems with your air brakes, on their own they are not capable of stopping the vehicle. When driving down steep hills always select a low gear.

On very steep hills you will find escape lanes. At the point that you realise that you have lost control of your vehicle, steer it into the escape lane.

The escape lane is a big sand pit, and will bring your vehicle to a controlled stop, hopefully not causing a danger you or to other road users.

The escape lane is a big sand pit, and will bring your vehicle to a controlled stop, hopefully not causing a danger you or to other road users.

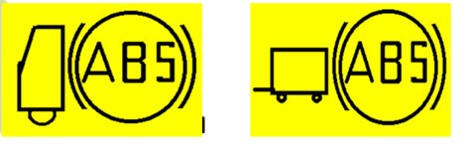

ANTI-LOCK BRAKING SYSTEM (ABS)

This is an electronic braking system that prevents your wheels locking up under heavy braking, maintaining steering control. The ABS is most useful in falling snow and heavy rain. They are least effective on Icey roads and loose surfaces. ABS allows you to steer and brake at the same time.

You must check that it is working before each journey. Displayed on the dashboard will be ABS lights similar to the ones below. They should go out shortly after the engine has started and your vehicle has reached a speed of 6 mph, if the lights stay on seek assistance.

Whether fitted with ABS or not, the way you brake is exactly the same. Braking in an emergency apply continuous firm pressure and when breaking generally brake in the normal way.

CADENCE BRAKING

ABS brakes sense when the wheels are about to lock, releasing and applying rapidly. If you do not have ABS You can emulate this process by pumping your foot-brake rapidly. In an emergency this could help you keep control of your vehicle. This type of braking is called cadence braking. If your vehicle is fitted with working ABS do not cadence brake as this will reduce the brakes effectiveness.

Air brakes are very powerful and have to be used very carefully and in good time. They are designed to stop weights in excess of 44 tons under control. All braking should be done in good time, gently and whilst travelling in a straight line. Braking on a bend or when turning can have a dramatic effect on your vehicles stability. If you are driving an articulated vehicle it could jack-knife. In bad weather such as snow and ice always brake when travelling in a straight line.